Reliable Valve Plate Installation with ESL Locknuts

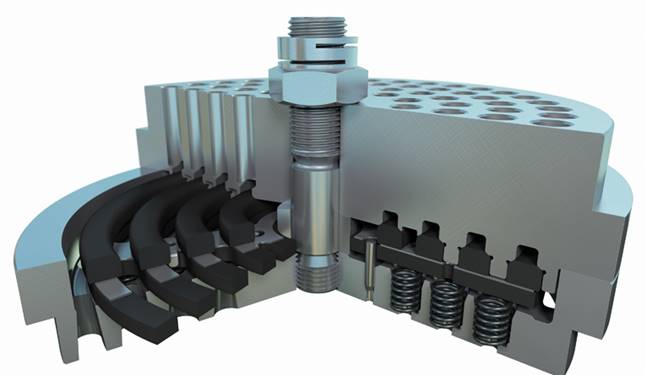

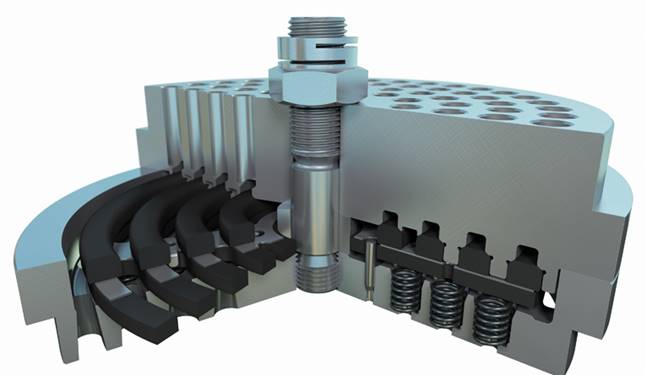

Traditional two-piece locknuts create installation complexity, risk of galling, and inconsistent clamp force on compressor valve plates. J.Lanfranco ESL locknuts simplify installation while ensuring precise torque, perpendicularity, and long-term reliability.

Improving Valve Plate Installation and Reliability

The Challenge: Traditional Solutions Create New Problems

Reciprocating compressors are expected to operate without failure in the oil and gas industry. Many manufacturers fasten valve plates using traditional Drake-style locknuts. While these nuts allow precise preload and help prevent stainless steel galling, they introduce multiple operational drawbacks:

- The two-piece assembly requires operators to follow a specific installation procedure.

- Multiple tools are needed to achieve proper torque, increasing the potential for human error.

- Limited availability, long lead times, and high cost complicate production planning.

For compressor OEMs, these issues affect installation consistency, reliability, and overall operational efficiency.

The Operational Impact: Inefficiency and Risk

Using Drake-style locknuts demands skilled operators and multiple checks for torque and alignment. Errors or variations during installation can lead to uneven clamp force, inconsistent performance, or even galling, creating costly maintenance issues later in the compressor’s lifecycle.

OEMs needed a solution that simplified installation while ensuring precise, repeatable clamp force on valve plates.

Defining a Practical Objective & Installation of ESL Locknuts

Following extensive evaluation, a major compressor manufacturer approved J.Lanfranco ESL locknuts for all valve plate assemblies. The ESL locknuts delivered measurable improvements across multiple critical areas:

- Provided a locking fastener with prevailing torque that functions independently of preload.

- Ensured 100% perpendicularity when required.

- Delivered consistent prevailing torque and a guaranteed coefficient of friction, enabling exact clamp force with every installation.

- Eliminated galling in stainless steel applications using a factory-applied, permanent, cost-effective anti-galling treatment.

Installation requires standard tools, simplifies procedures, and removes the reliance on specialized operator skills.

Proven Results: Reliability and Efficiency

With ESL locknuts, compressor OEMs achieved:

- Simplified valve plate installation

- Consistent, precise clamp force

- Reduced risk of galling and installation errors

- Cost-effective, durable fasteners with predictable performance

The ESL locknut has become the fastener of choice for compressor valve plates, providing reliability and repeatability that traditional two-piece nuts cannot match.