Ensuring Smooth Railway Traffic with the THU Locknut

Recurring fastener loosening at a busy railway diamond meant daily inspections. See how THU Locknuts solved the problem and maintained reliability in extreme conditions.

Explore our library of articles, guides, and technical resources.

Recurring fastener loosening at a busy railway diamond meant daily inspections. See how THU Locknuts solved the problem and maintained reliability in extreme conditions.

Shaker tables in mining operations are prone to downtime due to loosened screens under extreme shock and vibration. J.Lanfranco THU and ERM locknuts provide high repeatable locking, integrated washer support, and multiple install/removal cycles to keep plants running efficiently.

A busy Class 1 double diamond faced frequent loose and seized bolts, causing weekly maintenance headaches and high costs. J.Lanfranco THU locknuts provided predictable locking, eliminated weekly replacements, and saved $50,000 in six months.

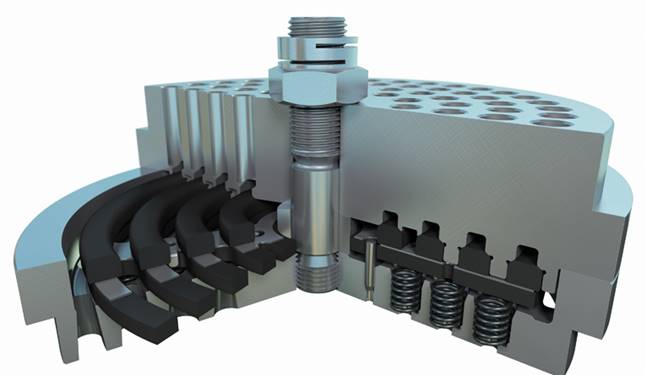

Traditional two-piece locknuts create installation complexity, risk of galling, and inconsistent clamp force on compressor valve plates. J.Lanfranco ESL locknuts simplify installation while ensuring precise torque, perpendicularity, and long-term reliability.

Vibration and collector shoe tension caused loose fasteners on power rail cover boards, risking safety and service disruptions. ERM locknuts provide a reliable, easy-to-install solution that keeps cover boards secure under daily train operations.

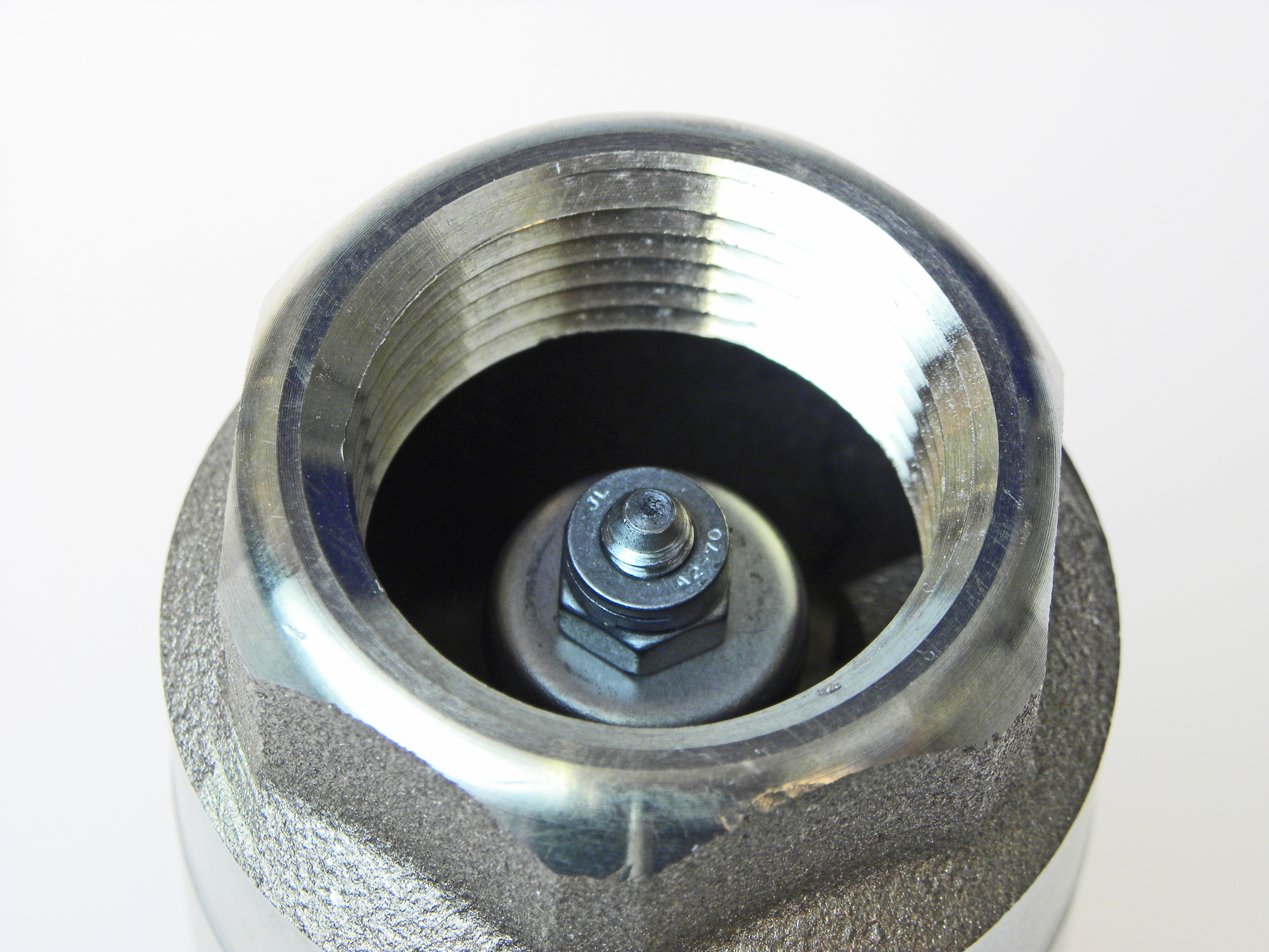

Seized locknuts during installation and maintenance were driving labor costs, downtime, and warranty risk for a compression check valve OEM. By switching to J.Lanfranco ESL locknuts, the manufacturer eliminated galling without anti-seize and standardized production at scale.

Sustained vibration and extreme temperatures make bolted joint failures a constant risk in cement production. A large European cement producer eliminated fastener-related downtime by installing J.Lanfranco ESL self-locking locknuts on critical ball mill assemblies.

When a major railway bridge collapsed under heavy freight traffic, the failure wasn’t visible bolt loosening—it was silent clamp force loss.