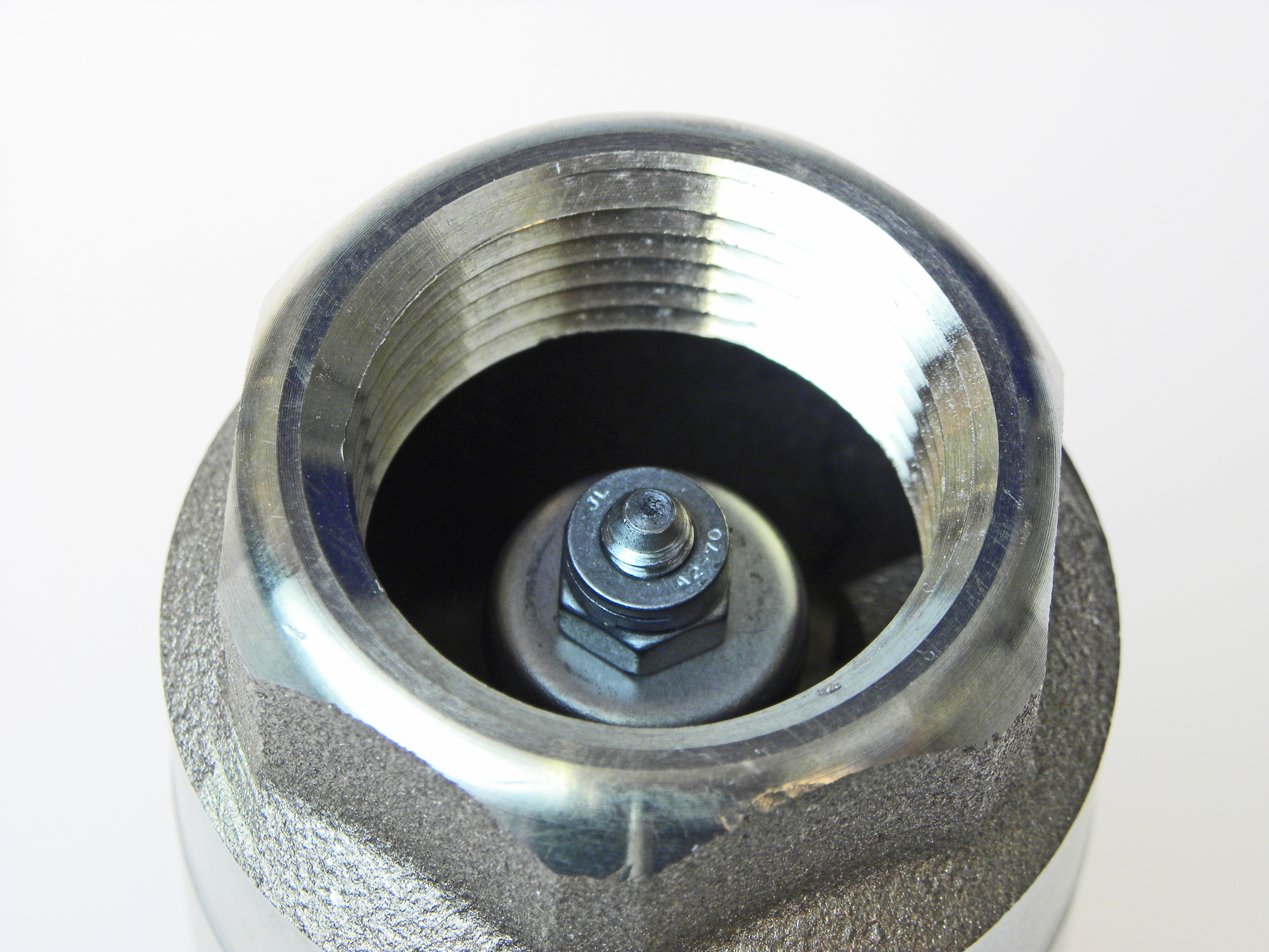

Eliminating Seized Nuts in Compression Check Valve Assembly

Seized locknuts during installation and maintenance were driving labor costs, downtime, and warranty risk for a compression check valve OEM. By switching to J.Lanfranco ESL locknuts, the manufacturer eliminated galling without anti-seize and standardized production at scale.

Eliminating Seized Nuts in Compression Check Valve Assembly

The Challenge: Installation and Maintenance Problems in Valve Manufacturing

Manufacturers of compression check valves frequently face problems with seized locknuts during installation and removal. Stainless steel fasteners, combined with repeated assembly cycles, create a high risk of galling.

While anti-seize pastes and greases are commonly used to mitigate this issue, they are not always acceptable. In many valve applications, lubricants introduce the risk of in-service contamination or chemical incompatibility.

As a result, manufacturers must contend with multiple operational challenges:

- Sorting and verifying locknuts prior to installation, increasing labor time and scrap

- Risk of contamination or adverse chemical reactions from anti-seize products

- Inability to remove seized nuts for required maintenance, leading to downtime and high warranty costs

What began as an installation issue quickly became a manufacturing efficiency and lifecycle cost problem.

The Operational Impact: Rising Costs and Reduced Serviceability

As seized nuts became more frequent, installation times increased and maintenance operations were delayed or prevented entirely. Failed removal attempts resulted in damaged components and unplanned valve replacements.

For the OEM, these issues translated into:

- Higher labor costs during assembly

- Increased downtime during service intervals

- Escalating warranty claims and customer dissatisfaction

A permanent solution was required—one that eliminated galling without introducing new risks.

Defining a Practical Objective & Installation of the ESL Locknut

J.Lanfranco worked with a major compression check valve manufacturer to identify a fastener solution that would improve installation efficiency, ensure removability, and eliminate the need for anti-seize compounds.

Nearly 150,000 valves are produced annually using ESL nuts.

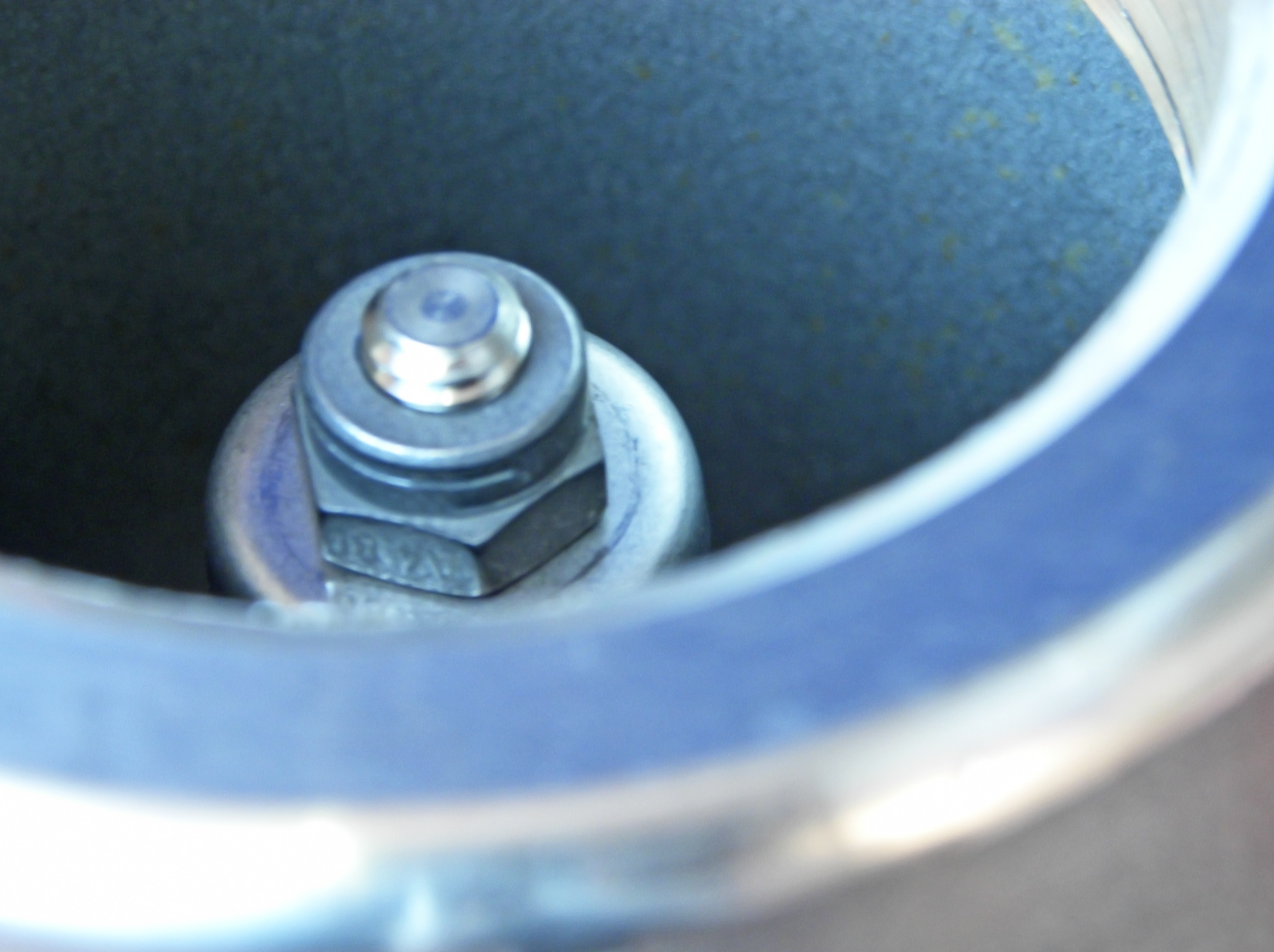

The OEM implemented J.Lanfranco ESL self-locking locknuts manufactured in passivated 304L stainless steel. The locknuts were tested on 300 valves under normal production and service conditions.

The objective was clear:

- Smooth, repeatable installation

- No galling or seizure

- Reliable removal during maintenance

- Compatibility with existing assembly procedures

Proven Results Enable Full-Scale Production

Following successful testing, the OEM standardized the ESL locknut across all major valve assemblies.

Installation issues related to seized nuts have been eliminated, maintenance operations are fully serviceable, and warranty costs associated with fastener failure have been significantly reduced.

Why Use the ESL Locknut?

Download the Full Case Study Here